Warehouse Automation That’s Business-Focused First, with OW Robotics

There’s an interesting paradox at play in the logistics and fulfilment industry right now. On the one hand, there’s been a huge rise in the demand for new facilities for the industry, with many companies that build and manage warehouse spaces able to sell new buildings before their construction is even complete. On the other hand, logistics and distribution companies are keen to bring in new digital initiatives, but only if the new tech sits alongside and “plays nice” with legacy infrastructure. Similarly, while new construction can’t happen fast enough, many companies are cautious as new technologies are gradually integrated into operations.

The 3PL, logistics, supply chain, and fulfilment sectors are not more conservative than any other for new technologies and digitization. Few companies in any vertical have the luxury of a “tear down and start again” approach to a digital transformation. Existing infrastructure — legacy stack — represents a significant investment, and careful integration of the new offers new possibilities and extends ROI on older systems.

Financial pressures on the logistics sector come from many sources; the sellers’ market for square footage and the high cost of container shipments are dogging the sector at present, despite the huge increase in demand for online retail fulfilment that’s taken place over the last five years (the last 20 months especially, of course). Recent changes have only proven that the markets for supply chain, logistics and distribution companies are highly volatile. Investments in new technology have to provide immediate operational efficiencies and be introduced gradually and with assured backward integration with legacy platforms.

The headline technologies that are making the pages of the industry news sites are robotics, automation, and the general field of IIoT (industrial IoT). Although these areas come along with adjectives like “seismic” and revolutionary”, the truth is that embarking on a mass robotic transformation seems to require a specialist knowledge of robots, hardware, control systems, and a whole phalanx of esoteric technologies that are perceived to be difficult and expensive to source.

We at Tech HQ have come across one company that’s fully cognizant of the pressures the industry is under currently: OW Robotics. Rather than comprising fresh-faced IT graduates, the company’s roots are fully industry-based, with years of experience in the detail of running a logistical business. The ways it deploys technology are designed to bring immediate operational benefit, with results manifest in immediate savings and gains in efficiency.

Its platforms are carefully integrated into the tech that companies already operate, extending the capabilities of a client’s investments and ensuring that whatever it introduces that’s new has a defined goal.

Return on investment in robotics is surprisingly quick, with the extensive gains made from day one compounding from the improvements made to efficiency and lowered costs. Here, the adjective “seismic” is perhaps appropriate — few other changes to operational methods have such a significant positive impact.

Nevertheless, there are understandable concerns about investment. Here, the truth is that all over the globe, the market leaders in supply chain, logistics and online retail are blazing the trail with their forward-looking deployments of robots and other automated systems. With options such as RaaS (robotics-as-a-service) as well as more traditional leasing models, means all the positive effects can be gained at a much lower than expected costs — in much the same way that companies like AWS and Google Cloud Platform provide facilities as-a-service that otherwise would require vast, upfront investment.

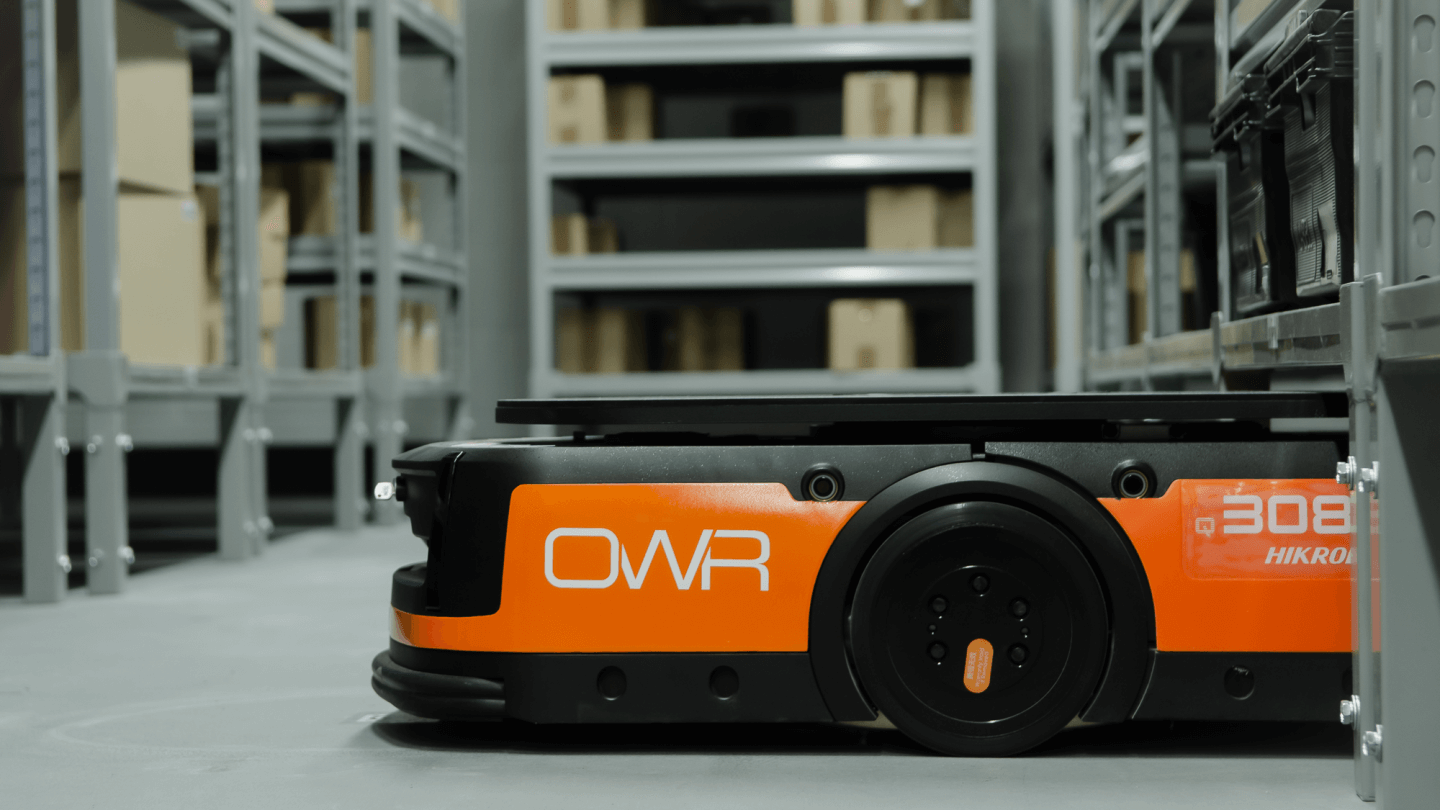

The “secret sauce” of the OW Robotics offering is that its devices work in different ways from expensive, fixed automated systems. Its hardware fits into existing facilities without need for remodelling space, installation of dedicated power lines or re-equipping entire facilities.

From day one, the dedicated team behind OW Robotics helps its clients refine how it works with advanced technology, perfecting operational processes to take full advantage of this proven tech.

Adjectives like “revolutionary” may be true (game-changing perhaps being a better fit); the results of autonomous systems and robotics in the industry can be immense. OW Robotics concentrates on the detail, on short-term gains being replicated many times over, and medium- to long-term change for its clients. The technology is used as a pivot to better operations, greater capacity and capability, lower costs, and overall better efficiency in the long term.

The arrival of any new technology platform (revolutionary or otherwise) needs acclimatization. That process need not be rushed, especially in an industry that’s expected to serve more customers faster, with fewer mistakes, and with an ever-rising standard of customer care. However, as the previous article in this series showed, the gains are there to be made. The manageable investment model, artfully integrated and deployed in step with the company’s existing strategies, can yield immediately noticeable positives.

To learn more about the different ways your own company’s automation and robotics journey can take you, start a conversation today with OW Robotics. In a market that’s increasingly driven by levels of accuracy, customer experience and sudden rises in demand, it pays to start planning early.