Reimagining engineering simulation software – a start-up’s story

After spending 10 years working on engineering problems and consulting with big and small firms on practical projects, Mihails Ščepanskis concluded that software tools needed to be reimagined. Current engineering simulation software was designed for R&D environments and set up to handle everything, but that put many potential users out of the picture.

Supporting big multinational firms such as car makers or electronics companies are thousands of smaller businesses that supply critical components. And these specialist firms don’t have the resources to pay for huge software licenses, especially when they’ll only be using a small fraction of the features.

To reorientate things, Ščepanskis co-founded CENOS in Riga, Latvia, to build engineering simulation software for industry-specific applications that prioritized the most important functions and spoke the right language. “The key issue that was holding back the market wasn’t necessarily the price, but the complexity of the software,” Ščepanskis told TechHQ.

To be successful, the CENOS team knew that it had to deliver tools that were quick to learn, even by engineers with no previous simulation experience. “Ease of use comes from the fact that the engineers have input and output data that they can understand,” explains Ščepanskis. “Our mission is to democratize simulation and bring it to the hands of every engineer.”

Pathfinding products

The firm’s first products focused on two application areas – induction heating and radio frequency (RF) simulation. Steel parts – such as gears, bearing housings, and pretty much every other component made from the material – need to be heat treated or hardened. And this happens by placing custom-designed induction coils around the part to heat it up.

Optimizing the design of these coils can save component makers a huge amount of time and energy. And this is where the CENOS software fits in – by ensuring that heating happens only where it’s needed. What’s more, the simplified user experience helps to speed up the design process too. Spanish firm 3D Inductors, which 3D prints induction coils out of pure copper, achieved 50% savings on design and production time using the engineering simulation software.

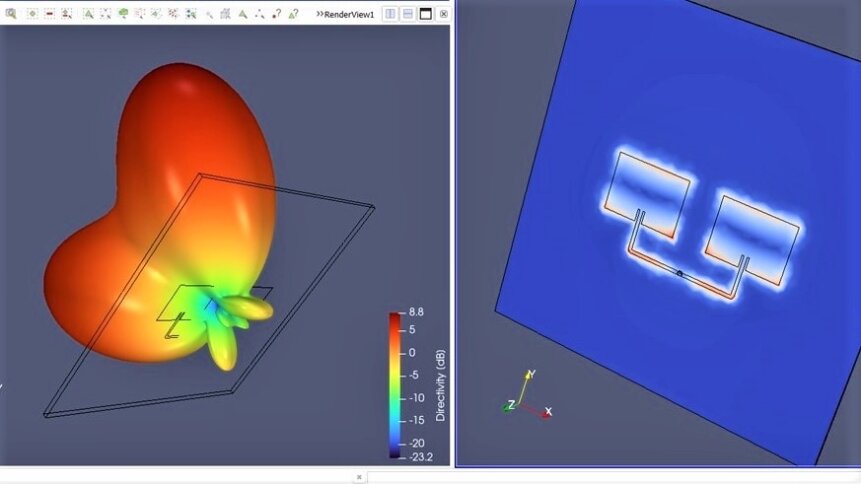

When it comes to RF simulation, CENOS’ original software fulfilled two roles. One application is antenna design – for example, to create specialist versions for satellites and drones. The other, more common use case is antenna placement. Using the engineering simulation software, device developers can quickly assess how other components will interfere with the performance of an antenna.

In products such as smart fridges, the tool allows designers to optimize the location of microstrip antennas. Data transmission and reception are enhanced by using the fridge door to help project the radiation pattern forwards into the kitchen. The vast increase in IoT devices has boosted the demand for antenna know-how. Straightforward simulation software helps product makers by reducing the amount of back and forth that’s required – for example, compared with outsourcing elements of the process. “We help companies to move that design back [in-house],” adds Ščepanskis.

High-flying use cases

He refers to a maker of pico satellites – tiny hand-sized orbiting devices – that brought forward its product launch by 12 months thanks to the time saved through RF simulation. Not only could the antenna design be optimized, but other elements of the satellite could be accounted for to check that satisfactory communications performance could still be achieved. For satellites, the energy budget is very constrained, and antennas have to operate as efficiently as possible.

This year, CENOS completely revised its RF application to go beyond antenna design and include many more capabilities, such as simulating multi-port networks and waveguides. The RF and induction heating simulations serve another purpose too, as the underlying software gives Ščepanskis and his colleagues a platform to build on.

Reusing the solvers, equations, and other software elements now makes it much more straightforward for CENOS to ramp up its applications list. Ščepanskis reveals that wireless charging, microwave applications, and many other industrially relevant use cases are in the launch pipeline and set to go live soon.

Users can run the engineering simulation software either locally or on an instance in the cloud. And while running operations in the cloud can be beneficial for larger jobs, there certainly isn’t a necessity to do so. In fact, it may be cheaper in the long run to carry out simulations directly on a desktop machine. Ščepanskis’ focus remains on ease of use and allowing customers to run the software in the way that suits them.

Developing a successful start-up relies on a number of factors and while having a compelling product is critical, it’s not the only consideration. Company location can play a role too. In CENOS’ case, the firm can tap into a flair for start-ups that increasingly goes hand-in-hand with the Baltic states.

Venture capital firm Index Ventures, which has offices in San Francisco, New York and London, has rated the Baltic nations of Estonia, Latvia and Lithuania as being the most start-up friendly in Europe, according to reports. Ščepanskis acknowledges that the environment is vibrant and credits Latvia’s tax system and corporate law as being favorable to start-ups.